Gold

There’s a rush to our gold sputtering targets.

DHF gold sputtering targets and evaporation pellets are custom designed and manufactured to keep more gold on the substrate and more cash flow on the balance sheet. That includes a target recycling program that quickly credits your spent target and delivers new ones in record time. Which explains why leading companies in aerospace, automotive, glass, medical and semiconductors have all discovered DHF gold in New Mexico.

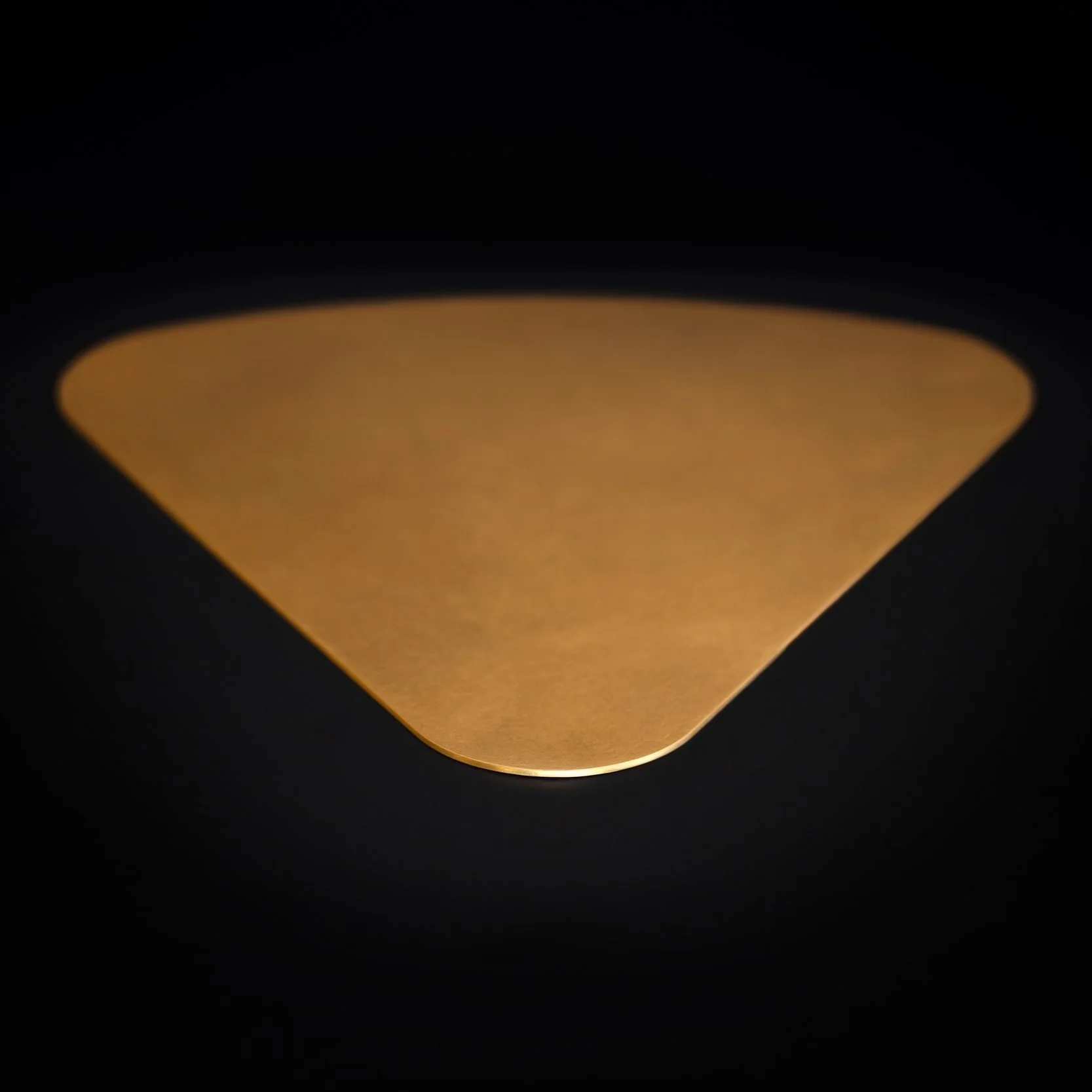

A Gold Upsilon sputtering target designed and manufactured by DHF Technical Products.

Gold Upsilon sputtering targets.

DHF Technical Products designs and manufactures Gold Upsilon targets for the large installed base of leading companies and institutions who run MRC/KDF sputtering systems.

With their flexible design and continued availability of parts and service, MRC/KDF systems have a proven track record and continue to play an important role in the thin film industry.

Our Gold Upsilon targets are fabricated to the exacting specifications of your MRC/KDF sputtering systems to help them operate at maximum efficiency.

A Gold Delta sputtering target.

Custom designed and manufactured gold sputtering targets.

Our innovative gold targets are designed and manufactured in custom diameters, custom shapes, custom thicknesses and custom purities up to 99.99%. We produce one-of-a-kind designs and materials for both planar and rotary targets. Each gold target is designed to fit your coater to produce the most efficient sputtering outcome possible. Each custom gold target is manufactured in our ISO-9001 Certified factory in Rio Rancho, New Mexico.

Lowering gold sputtering target cost of ownership.

Let DHF Technical Products reimagine your gold sputter targets from beginning to end to lower the cost of target ownership. We offer full lifecycle support from design and manufacturing to shield cleaning and spent target refining/recycling. Everything we do is designed to help extend the life of your gold sputtering targets and reduce your long term costs.

Working capital solutions from the gold sputtering target experts.

Our state-of-the-art R&D group can help identify designs and materials to optimize your gold sputter coating performance. The precious metal sputtering target experts at DHF Technical Products can help you manage your precious metal spend so you can keep more of your working capital and increase cash flow.

At DHF Technical Products, our specialty is helping gold sputtering target customers secure a steady, high-quality supply of critical materials during turbulent metal markets. If your manufacturing process depends on gold sputtering targets, now is a good time to evaluate your future needs. Or, as we like to say, “Let’s talk targets.”

Gold sputtering target applications.

Gold is a precious metal with a range of physical properties that make it uniquely suited to a variety of thin film applications. Gold is soft, dense, malleable, ductile and is sought out for its electrical and thermal conductivity. This makes gold an essential element in a number of growing industries. Thin films of gold are often used as layers or coatings in the manufacturing processes of semiconductors, integrated circuits, sensors, solar cells, flat panel displays, LED and photovoltaics, optical devices, data storage, batteries, medical devices and more.

Our gold sputtering targets are designed to give you a better return on your precious metal investment. One of the many reasons they are the choice of leading PhDs and CFOs in a variety of industries.

Aerospace.

Gold’s properties as a dependable conductor and connector make it ideal for use in space vehicle circuitry. A gold-coated polyester film is often used to reflect infrared radiation to help regulate temperatures of spacecraft. The glass visor on the helmet of an astronaut's space suit is coated with a thin film of gold to protect eyes and skin.

Medical Devices.

Tiny amounts of gold from a sputtering target play an important role in surgical instruments, life-support devices and other medical electronics equipment. The fast-growing point-of-care test industry uses gold sputtering targets and other precious metals for innovative diagnostic tests, like blood glucose monitoring products, which are helping people get accurate, life-saving test results in minutes.

Semiconductor Chip Manufacturing.

Expensive semiconductor chips often use high purity gold sputtering targets. Requirements can range from 99.99% (4 nines or 4N) and 99.999% (5 nines or 5N) purity which are generally higher than requirements for products like solar cells or flat-panel displays.

Photovoltaic Production.

Gold sputtering targets are used in the coating of the back electrode of solar thin-film cells and crystalline silicon solar cells as well as the back electrode of the solar thin-film battery.

Optical Devices.

Gold sputter coatings are used in a variety of optical devices including smartphones, optical disc players, digital cameras and car lenses. Thin films of gold are also used in DNA sequencing, biometric identification and lenses for monitoring spacecraft.

Gold evaporation pellets without evaporating profits.

DHF gold evaporation pellets are the choice of both Fortune 500 companies and smaller coating operations. The reason? Our gold evaporation pellets are as reliable in a vacuum as they are on your budget. That includes DHF state-of-the-art analysis methods which immediately credit your spent pellets and turn around new ones faster than ever before.